Electrically Conductive Adhesive

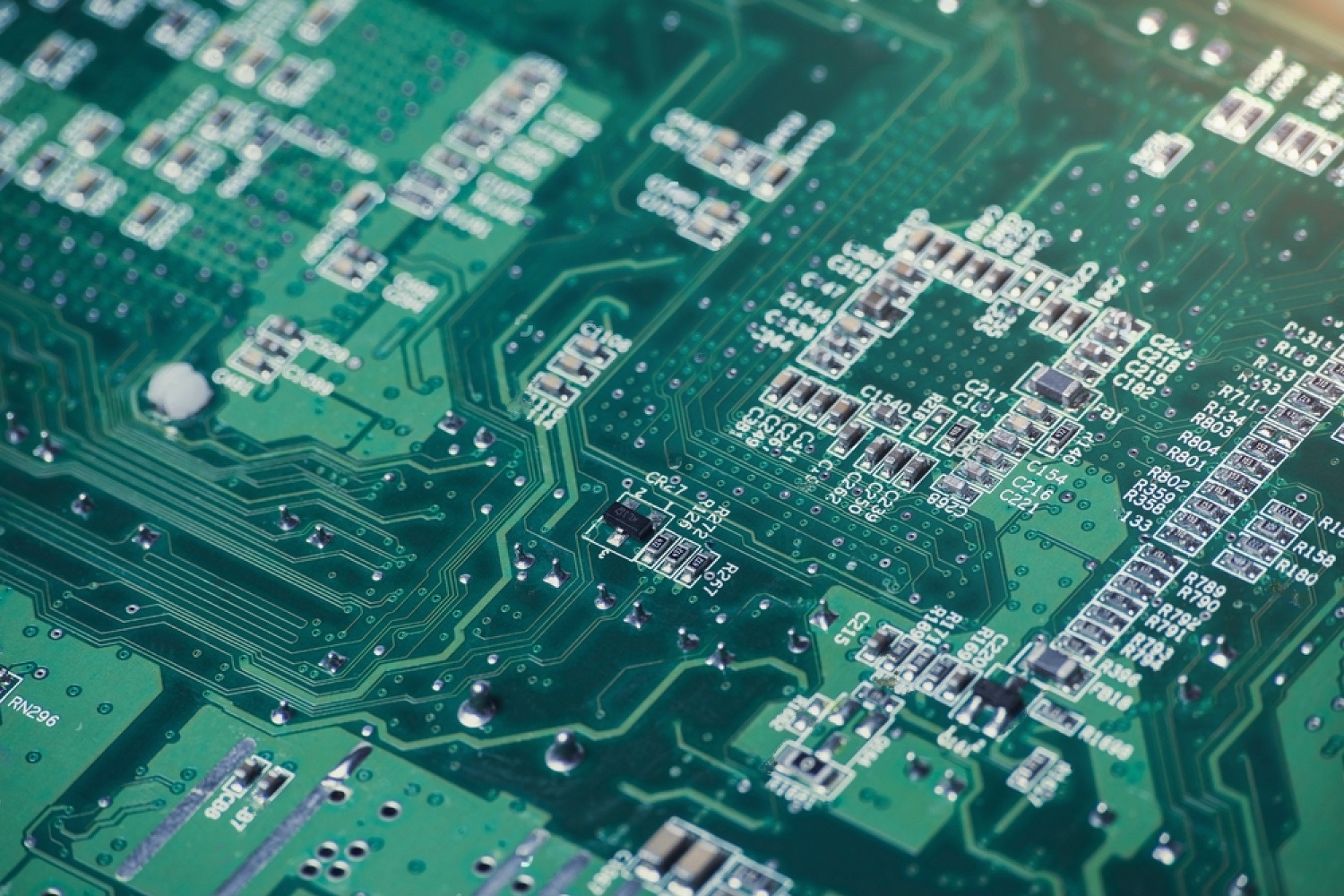

Electrically conductive adhesives are generally used in electronics industry for bonding parts where it is desired for the electrical current to travel between. Although it is possible to use the soldering process in some cases (attaching components to PCBs), for applications that includes electronic components which are highly sensitive to temperature, it is better to use electrically conductive adhesives. That is because unlike adhesives, the soldering iron and the high temperature of the liquid solder can inflict irreversible damage on the electrical components.

Electrically conductive adhesives can be used for various application in electronics sector:

- Coating and Bonding of RFID chips

- EMI/RF Shielding

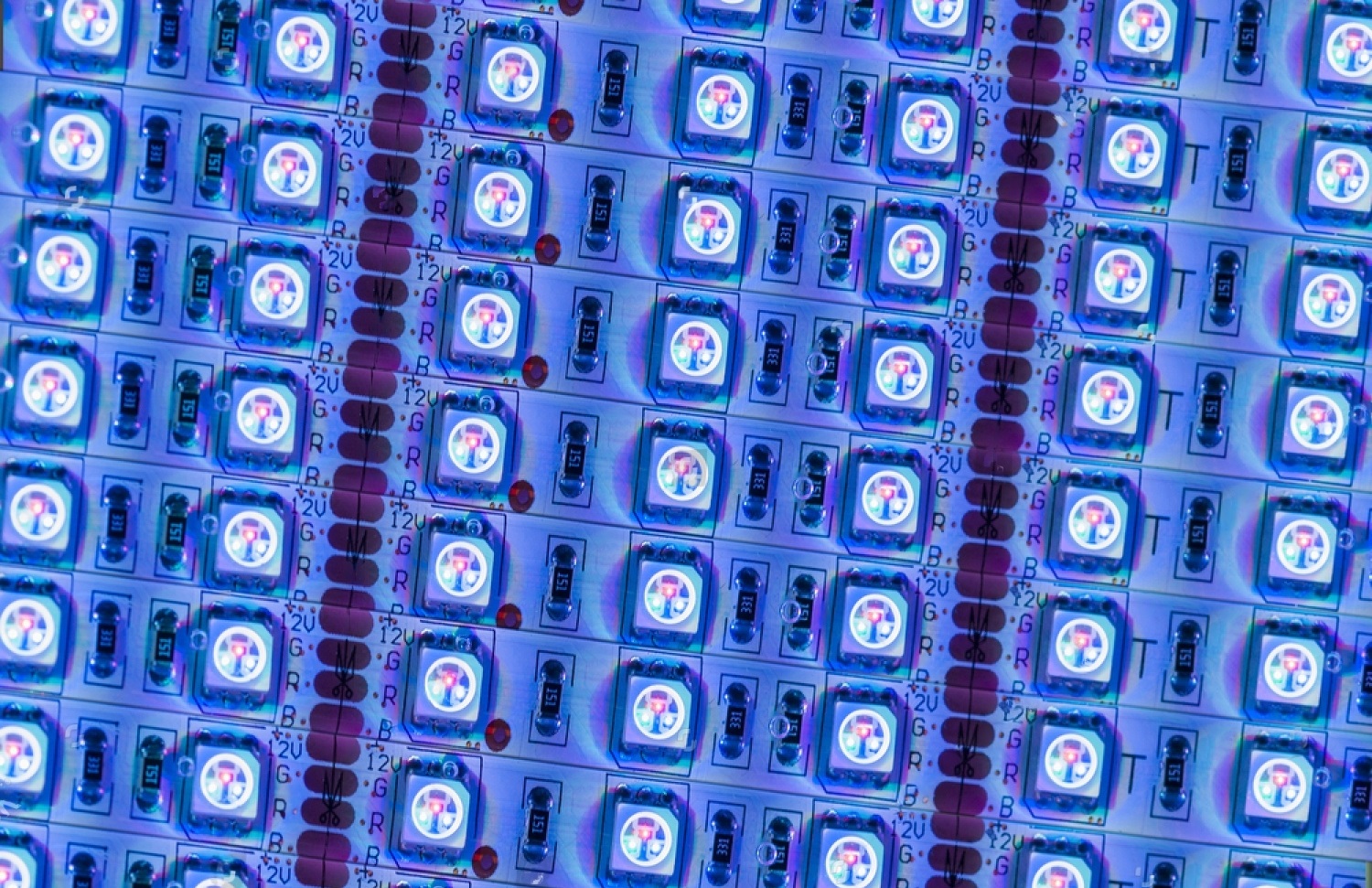

- Mounting LEDs

- Manufacturing of Touch Panels

- Screen-printing electrical circuits on kapton and mylar

and so on…

How to Select the Correct Adhesive

Not every adhesive can be used for every application. To select the correct adhesive for each process, there are certain points to consider.

- Electrical Conductivity: The electrical conductivity of an adhesive depends on the filler material that the adhesive contains. Different materials have different electrical conductivities.

- Gap Filling: The chosen adhesive should be able to fill the gaps in order to create a continuous line.

- Curing Properties: Does the adhesive need to be cured in a matter of seconds or does it require some adjustment time? Does the adhesive require heat to be cured or should it be cured in room temperature?

- Environmental Conditions: What are the environmental conditions that the adhesive will be subjected to (humidity, temperature, existence of aggressive chemicals etc.)?

- Tests: Which test should the adhesive be able to pass?

etc.

Properties of Electrically Conductive Adhesives

A TDS (technical data sheet) is an excellent source to compare the effectiveness of two different products as long as the reader knows what they are looking at. Here are some properties to pay attention to when looking for an electrically conductive adhesive.

Dielectric Strength

Dielectric strength can be explained as the maximum voltage that a material can withstand before breaking down. The unit of the Dielectric Strength in SI (System International) is V/m (Volts per meter). This property, which is specific for electrically insulating materials, is important for many potting and encapsulation processes.

Relative Permittivity

Relative Permittivity, also known as Dielectric Constant, is the measurement of the electrical energy storage ability of a material.

Electrical Resistivity

Electrical Resistivity, also known as Volume Resistivity, is the measurement of how strongly a material can resist electric current. The unit of Electrical Resistivity in SI is Ω*m (ohm times meter). Conductive materials need to have low Electric Resistivity.

Adhetron Products

As Adhetron, we offer a variety of electrically conductive adhesives under the name of ELTECH Series. Our products are suitable to use in various industries such as:

- Automotive

- Aerospace

- Telecom

- Electronics

and so on… Do not hesitate to contact us if you have any questions.

https://en.wikipedia.org/wiki/Dielectric_strength

https://www.techtarget.com/whatis/definition/dielectric-constant

https://nts.com/services/testing/materials/volume-and-surface-resistivity/