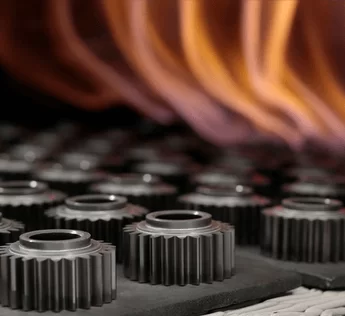

Powder Metallurgy and Sintering

Powder Metallurgy and Sintering, As a cost-effective and efficient way to produce complex parts with high precision and tight tolerances, powder metallurgy is a manufacturing process which involves the production of metal parts from metal powders. This process involves, several steps including powder production, compaction, and sintering.

- Production: Metal powders can be produced through a variety of methods including mechanical comminution, chemical reduction, and electrodeposition. Once the metal powders are produced, they are generally mixed with a binding agent to form a homogenous mixture.

- Compaction: This step is about pressing the metal powder mixture into a desired shape using a tool or die. Compaction can be done by using methods like, cold pressing, hot pressing, and isostatic pressing. This step is extremely important because the compaction step determines the density and the strength of the final product.

- Sintering: In this step the compacted metal powder mixture is heated to a temperature below its melting point. During sintering, the binding agent is removed, and the metal particles fuse together to form a solid mass. Sintering can be done through different methods such as conventional sintering, hot isostatic pressing (HIP), and spark plasma sintering (SPS).

Sintering process is extremely important because it determines the final properties of the product like its ductility and surface finish. The sintering process can also be used to improve the dimensional accuracy of the final product by removing shrinkage and warpage. During the removing process, specialized equipment and expertise are required. This is where Adhetron’s unique graphite-based release agent resistant to temperatures up to 2000oC under hard vacuum for sintering trays comes to your aid. Gra-C 0701’s unique formula is designed to act as an anti-stick mold release agent for graphite trays operating in high temperatures.