Understanding the Basics of CNC Machines

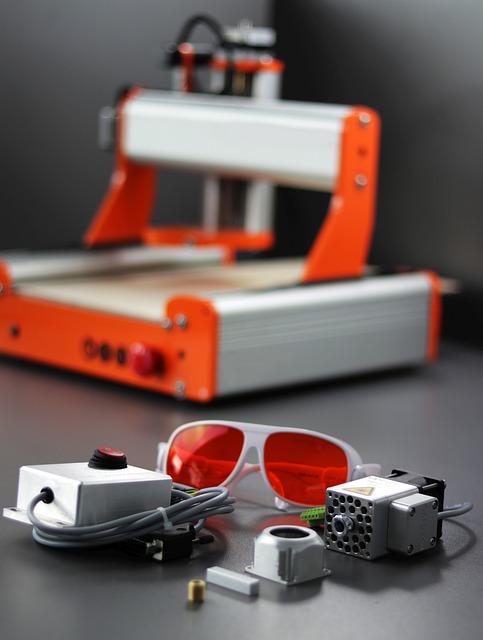

What Is A CNC Machine? This question is one that many people ask when they first hear about these advanced machines. CNC, which stands for Computer Numerical Control, refers to the process of using computer programs to automate the operation of machine tools. In simple terms, a CNC machine is a manufacturing tool that uses pre-programmed computer software to control and operate a variety of complex machinery, such as lathes, routers, and mills. These machines are used in a wide range of industries, including automotive, aerospace, and manufacturing, to create precision parts and components with incredible accuracy and speed.

One of the key features of a CNC machine is its ability to follow precise instructions from a computer program, which allows for the production of intricate and complex parts that would be nearly impossible to manufacture manually. This level of precision and automation has revolutionized the manufacturing industry, making it possible to produce high-quality components in a fraction of the time it would take using traditional methods.

Over the years, CNC machines have evolved to include a wide range of capabilities and features, making them an essential tool for modern manufacturing processes. These machines can perform a variety of tasks, such as cutting, drilling, and shaping materials like metal, wood, and plastic, with incredible accuracy and efficiency. With the right programming and tooling, CNC machines can produce parts with tolerances as tight as a few thousandths of an inch, making them an indispensable tool for industries that demand precision and repeatability.

The History and Development of CNC Machines

The development of CNC machines can be traced back to the early 20th century when the first numerical control (NC) machines were introduced. These early machines used punched cards to control the movement of machine tools, laying the groundwork for the more advanced CNC machines that we know today. In the 1950s and 1960s, the first computer-controlled machines began to emerge, revolutionizing the manufacturing industry and paving the way for the modern CNC machines that are used today.

As technology continued to advance, so did the capabilities of CNC machines. The introduction of CAD (Computer-Aided Design) and CAM (Computer-Aided Manufacturing) software allowed for greater automation and efficiency in the design and production of parts, further expanding the capabilities of CNC machines. Today, CNC machines are equipped with advanced features such as multi-axis control, high-speed machining, and automatic tool changers, making them more versatile and capable than ever before.

The development of CNC machines has also led to the emergence of new manufacturing processes, such as 3D printing and additive manufacturing, which have further revolutionized the way that parts and components are produced. These technologies, which are based on the principles of CNC machining, have opened up new possibilities for creating complex geometries and structures that were previously impossible to manufacture using traditional methods.

The Types of CNC Machines and Their Applications

There are several different types of CNC machines, each with its own unique capabilities and applications. Some of the most common types of CNC machines include:

| Type of CNC Machine | Applications |

|---|---|

| CNC Milling Machine | Used for cutting and drilling operations on solid materials such as metal and plastic |

| CNC Lathe Machine | Primarily used for shaping and turning operations on cylindrical workpieces |

| CNC Router | Designed for cutting, shaping, and engraving operations on wood, plastic, and composite materials |

These are just a few examples of the many types of CNC machines that are available, each with its own set of capabilities and applications. From small desktop machines to large industrial systems, CNC machines can be found in a wide range of industries and applications, from small-scale prototyping to high-volume production.

In addition to their use in traditional manufacturing processes, CNC machines are also used in the production of complex components for industries such as aerospace, automotive, and medical devices. These machines are capable of producing intricate parts with tight tolerances and complex geometries, making them an essential tool for industries that demand precision and repeatability in their manufacturing processes.

The Advantages of Using CNC Machines

The use of CNC machines offers a number of significant advantages over traditional manufacturing methods. Some of the key benefits of using CNC machines include:

- Precision and Accuracy: CNC machines can produce parts with incredibly tight tolerances and high levels of precision, ensuring that every part is consistent and reliable.

- Efficiency and Productivity: CNC machines can operate 24/7 with minimal human intervention, making them incredibly efficient and productive compared to traditional manufacturing methods.

- Flexibility and Versatility: CNC machines can be easily reprogrammed to produce different parts and components, making them a versatile tool for a wide range of applications.

- Automation and Labor Savings: CNC machines require minimal human intervention, reducing the need for manual labor and streamlining the manufacturing process.

These are just a few examples of the many advantages of using CNC machines in modern manufacturing processes. With their ability to produce high-quality parts with incredible precision and efficiency, CNC machines have become an essential tool for industries that demand the highest levels of quality and reliability in their products.

The Future of CNC Machines: Innovations and Trends

As technology continues to advance, so too will the capabilities of CNC machines. The future of CNC machines is likely to be shaped by a number of key innovations and trends, including:

- Advanced Materials and Processes: The development of new materials and manufacturing processes will expand the capabilities of CNC machines, allowing for the production of even more complex and advanced components.

- Integration with Industry 4.0: CNC machines will become increasingly integrated with the principles of Industry 4.0, such as IoT (Internet of Things) and data-driven manufacturing, leading to more efficient and connected manufacturing processes.

- AI and Machine Learning: The use of AI and machine learning algorithms will enhance the capabilities of CNC machines, allowing for more adaptive and intelligent manufacturing processes.

These are just a few examples of the many innovations and trends that are likely to shape the future of CNC machines. As technology continues to evolve, CNC machines will continue to play a central role in the manufacturing industry, driving innovation and efficiency in the production of high-quality components and products.

In conclusion, CNC machines are a fundamental tool for modern manufacturing processes, offering a level of precision, efficiency, and versatility that is unmatched by traditional manufacturing methods. As technology continues to advance, so too will the capabilities of CNC machines, shaping the future of the manufacturing industry and driving new innovations and trends in the production of high-quality components and products.